HYDRAULIC SWING BEAMNC SHEARING MACHINE

Our swing shears use advanced hydraulic systems and intelligent CNC technology to ensure high-precision and high-efficiency cutting. At the same time, they are easy to operate, low in noise, sturdy and durable, and suitable for various metal processing needs.

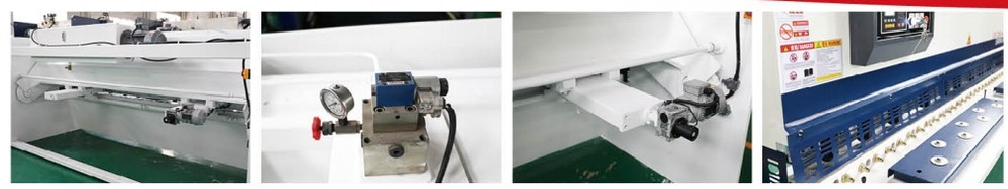

Product display

Product advantages

High-precision shearing

ensures the flatness and smoothness of the cutting surface and reduces the grinding work after processing.

Stable hydraulic system

provides strong shearing force and low-noise operation, improving the comfort of the working environment.

Intelligent control

easy to operate, can realize automatic cutting, and greatly improve production efficiency.

Sturdy and durable

made of high-quality steel, with long life and high fatigue resistance.

Product specification parameter table

| Type | Cutting thickness | Cutting length | Cutting ange | Meterail strength | Travel times | Powet | Dimension |

|---|---|---|---|---|---|---|---|

| (mm) | (mm) | (°) | (KN/cm) | (times/minute) | (Kw) | Lxwxh (mm) | |

| 4x2500 | 4 | 2500 | 1°30′ | ≤450 | 10 | 5.5 | 3040×1610×1620 |

| 4×3200 | 4 | 3200 | 1°30′ | ≤450 | 10 | 5.5 | 3840×1610×1620 |

| 4×4000 | 4 | 4000 | 1°30′ | ≤450 | 8 | 5.5 | 4600×1700×1700 |

| 4×6000 | 4 | 6000 | 1°30′ | ≤450 | 5 | 7.5 | 6460×2100×3200 |

| 6x2500 | 6 | 2500 | 1°30′ | ≤450 | 10 | 7.5 | 3040x1610×1620 |

| 6×3200 | 6 | 3200 | 1°30′ | ≤450 | 9 | 7.5 | 3840×1610×1620 |

| 6×4000 | 6 | 4000 | 1°30′ | ≤450 | 8 | 7.5 | 4620×1750×1700 |

| 8×2500 | 8 | 2500 | 1°30′ | ≤450 | 10 | 7.5 | 3040×1700×1700 |

| 8×3200 | 8 | 3200 | 1°30′ | 5450 | 8 | 7.5 | 3860×1700×1700 |

| 8×4000 | 8 | 4000 | 1°30′ | ≤450 | 8 | 7.5 | 4640×1700×1700 |

| 8×5000 | 8 | 5000 | 1°30′ | ≤450 | 8 | 7.5 | 5400×2400×2000 |

| 10×3200 | 10 | 3200 | 2° | ≤450 | 9 | 11 | 3860×1700×1700 |

| 10×4000 | 10 | 4000 | 2° | ≤450 | 8 | 11 | 4650×2100×2000 |

| 10×6000 | 10 | 6000 | 1°30′ | ≤450 | 5 | 15 | 6500×2100×2300 |

| 12×4000 | 12 | 4000 | 1°40′ | ≤450 | 8 | 18.5 | 4680×2150×2000 |

| 12×5000 | 12 | 5000 | 2° | ≤450 | 6 | 18.5 | 5900×2150×2000 |

| 12×6000 | 12 | 6000 | 2° | ≤450 | 5 | 18.5 | 6900×2600×2700 |

| 12×8000 | 12 | 8000 | 2° | ≤450 | 5 | 18.5 | 9000×3500×3500 |

| 16×4000 | 16 | 4000 | 2°30′ | ≤450 | 8 | 18.5 | 4650×2150×2200 |

| 16×5000 | 16 | 5000 | 2°30′ | ≤450 | 6 | 18.5 | 5900×2600×2700 |

| 16x6000 | 16 | 6000 | 2°30′ | ≤450 | 5 | 22 | 6900×2700×2700 |

| 16×8000 | 16 | 8000 | 2°30′ | ≤450 | 5 | 22 | 9000×3500×3500 |

| 20×4000 | 20 | 4000 | 3° | ≤450 | 5 | 22 | 4850×2600×2400 |

| 20×6000 | 20 | 6000 | 3° | ≤450 | 4 | 22 | 6700×3000×3000 |